Second Car Killer.

More often than not, two-car households would talk about their first car being a requirement, but their second car as a convenience.

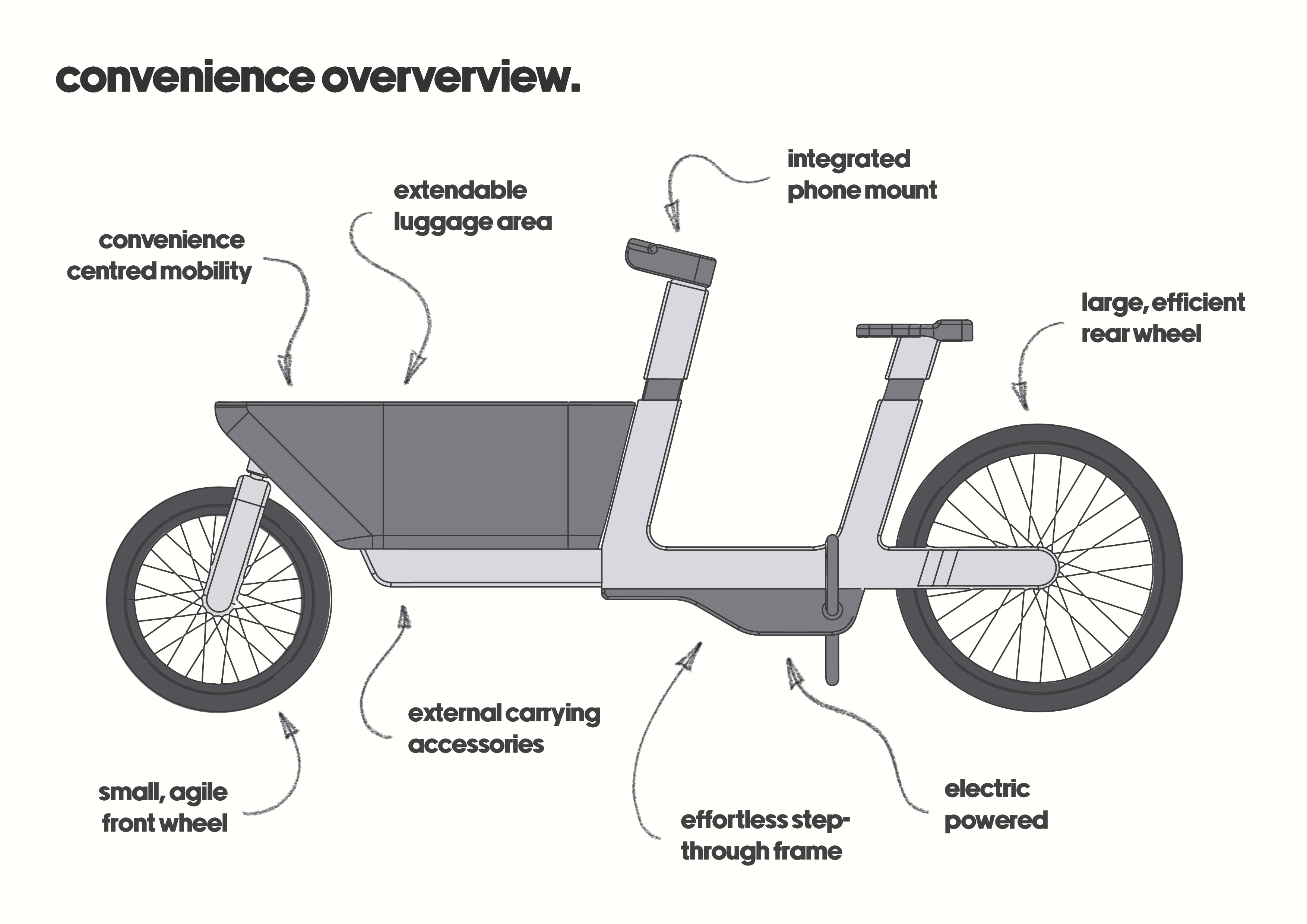

The word ‘convenience’ stuck with me, forming the project into an exploration of how we could develop a transportation method that combines the benefits of owning and riding a bike (such as avoiding traffic, getting exercise, and easy parking) with the convenience typically associated with a second car.

How could we flip our current assumptions about cars and bikes on its head, to get the best of both worlds?

Ultimately, this concept aims to support the individual conveniences offered by the second car, including ample luggage space for items like sports gear, as well as pockets for smaller items usually kept in a car's centre console or on the passenger seat.

If you had to ride around with a massive amount of luggage space when you didn’t always need it, how convenient would that actually be?

For this reason, the luggage area can be collapsed or expanded at any time, released with the push of a lever on the handlebar. This means you can effortlessly take your backpack, coat and keys to work in the morning, and not have to worry when you forgot that you needed to do your family’s weekly shop on the way home.

Yes, you could take your regular items in a pannier bag, or buy a bottle holder for your water, but that isn’t convenient.

Instead, this concept aims to suitably carry your everyday ‘things’ without having to go out of your way at any point in time.

Yes, you could take your regular items in a pannier bag, or buy a bottle holder for your water, but that isn’t convenient.

Instead, this concept aims to suitably carry your everyday ‘things’ without having to go out of your way at any point in time.

Exhibition model

Also check out these!

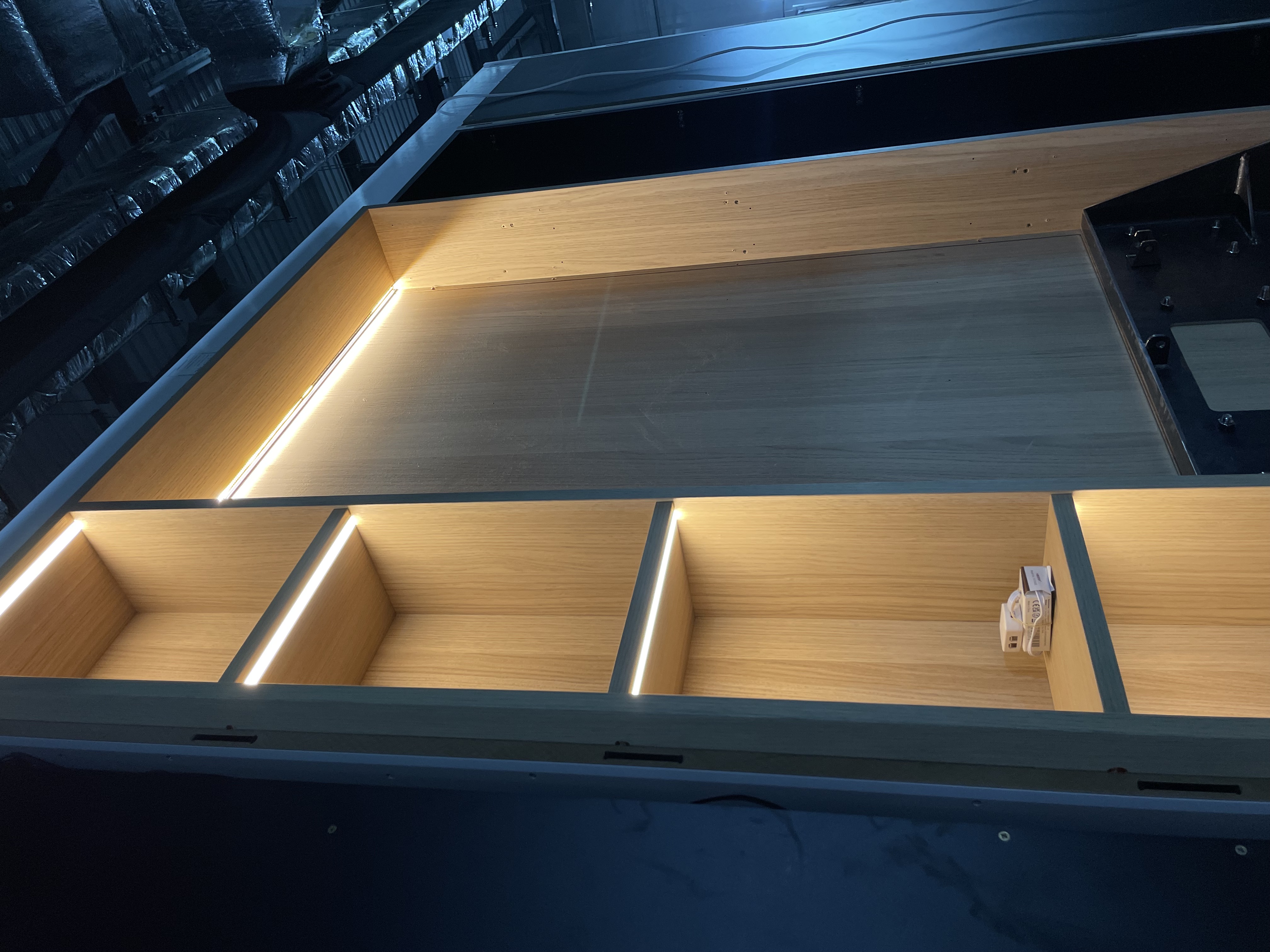

Smart Walls - Plenti Space

Role: Industrial Designer

Plenti is addressing Europe’s housing affordability crisis with ‘Smart Walls’ that create affordable, sustainable, and comfortable spaces, which are commercially viable for property developers and landlords.

Smart walls expand spaces on demand - increasing utilisation and livability of a property. With Plenti developers reduce rents for tenants by 20%, while increasing rent premiums by 10% per sqm, and lowering the environmental impact by 25% per flat.

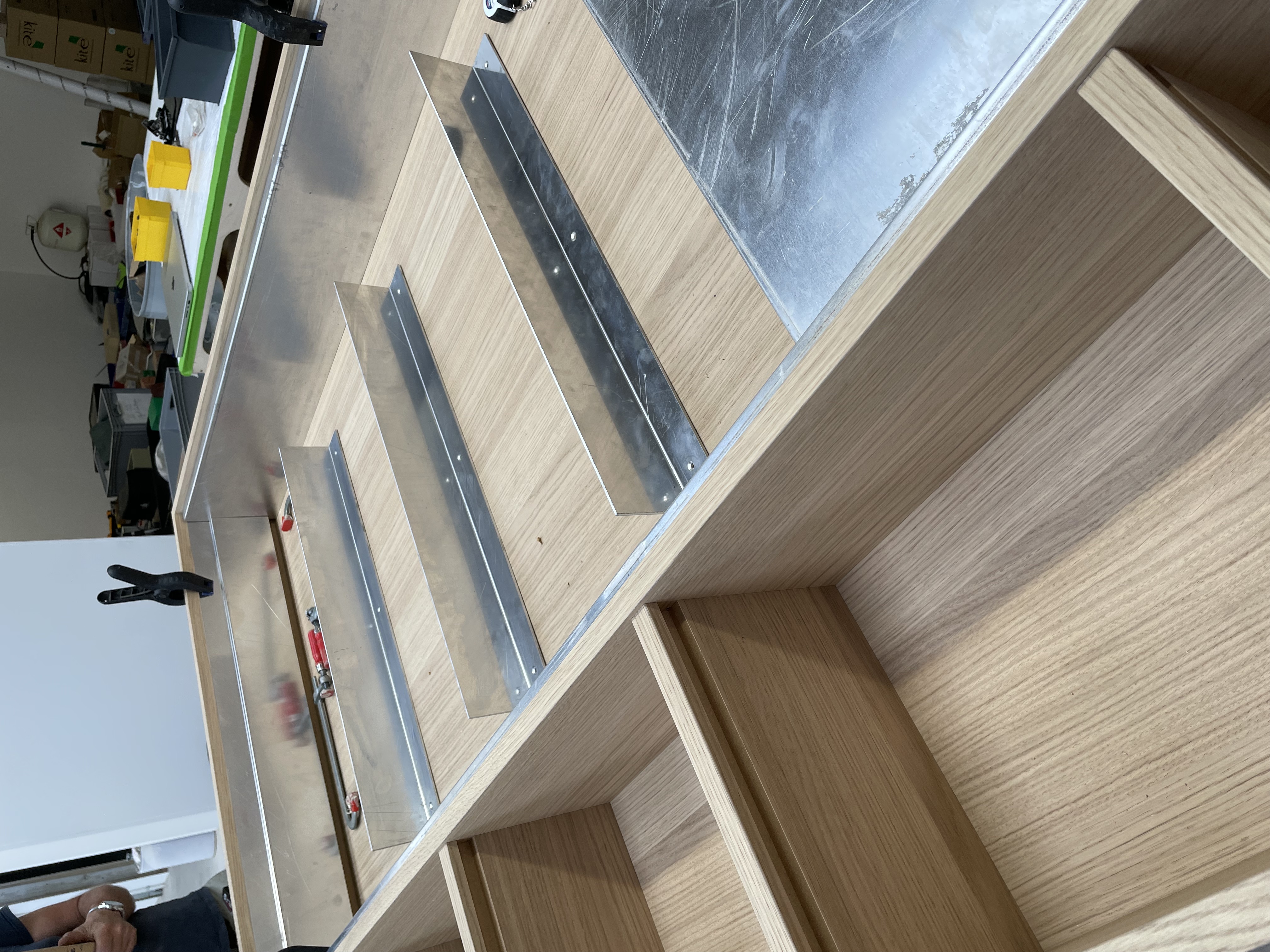

Prototype making

Showroom display

Also check out these!

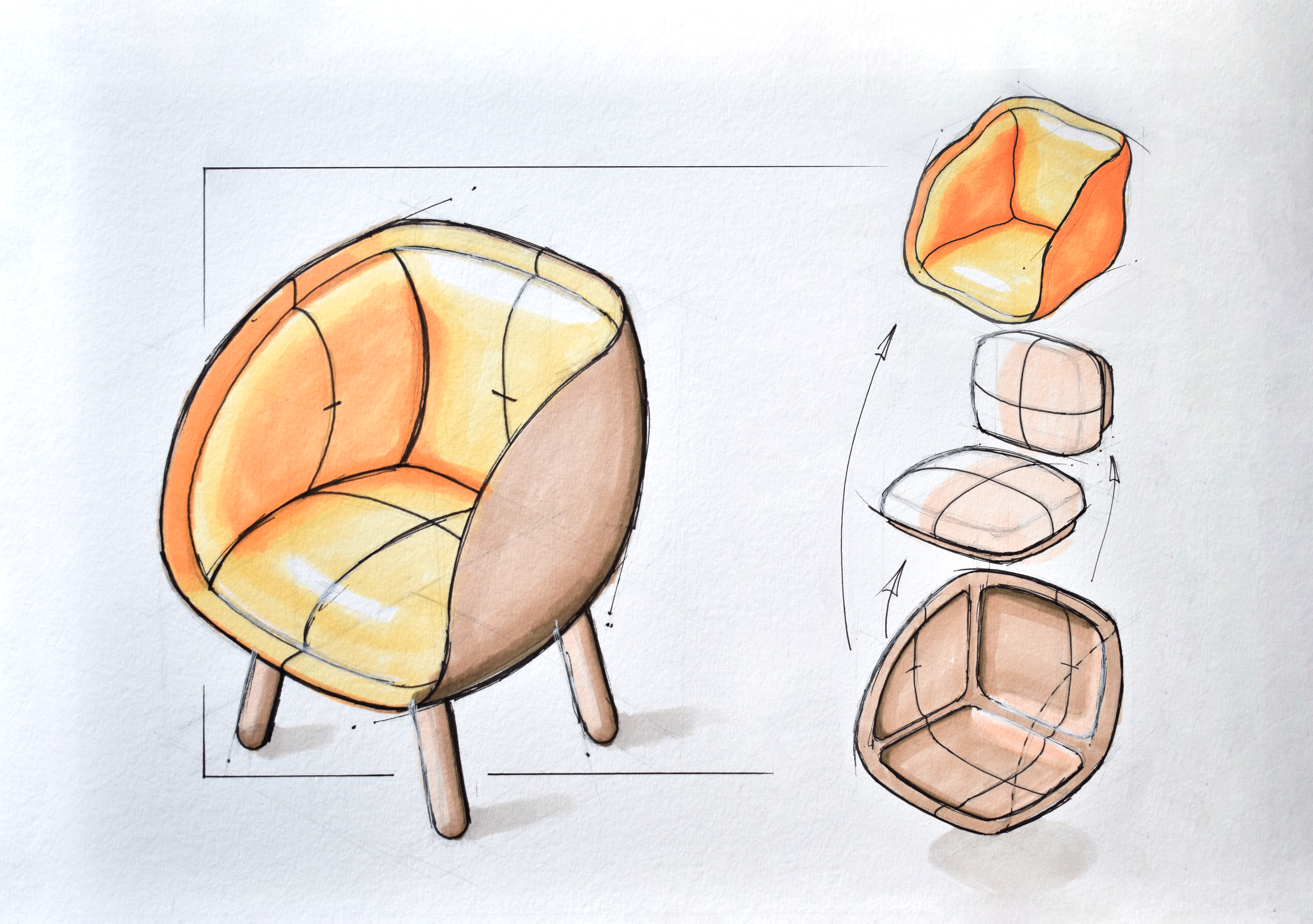

How can repairable upholstery help a chair last longer?

Over time, chairs haven’t really changed. Since this style of chair was created, upholstery has been permanently stapled in place to keep manufacturing costs low.

But what if you could easily change upholstery based on your latest décor?

People could have a completely new aesthetic with minimal effort and cost. There would be much less furniture waste. There is even possibility to create a market for buying and selling lower-cost covers. Heck, even an entirely new ecosystem can be created based off changing this one archetype.

This chair is an exploration into what the next step towards this ecosystem could look like.

The simple two-part design allows it to still feel like a traditional chair, while also overcoming many of the difficulties found in traditional upholstery. It is also as easy as possible for the consumers to remove and install, yet offers an equivalent finish to the current chairs.

While not shown in the photos, the ambition is to use magnets to join both sections along the exposed flange, and will be my next steps in developing this concept.

While not shown in the photos, the ambition is to use magnets to join both sections along the exposed flange, and will be my next steps in developing this concept.

Also check out these!

Modular lighting system

This modular, rechargeable LED light system allows users to effortlessly switch between diffusers, shades, and bodies, adapting to any lighting need with ease.

The design uses a common lighting module, built around standardised connections and core design principles. The single module alone has the potential to evolve into a versatile collection with a wide range of applications.

While still in development, the foundational modular system is nearly complete, ready to expand into new forms soon.

Also check out these!

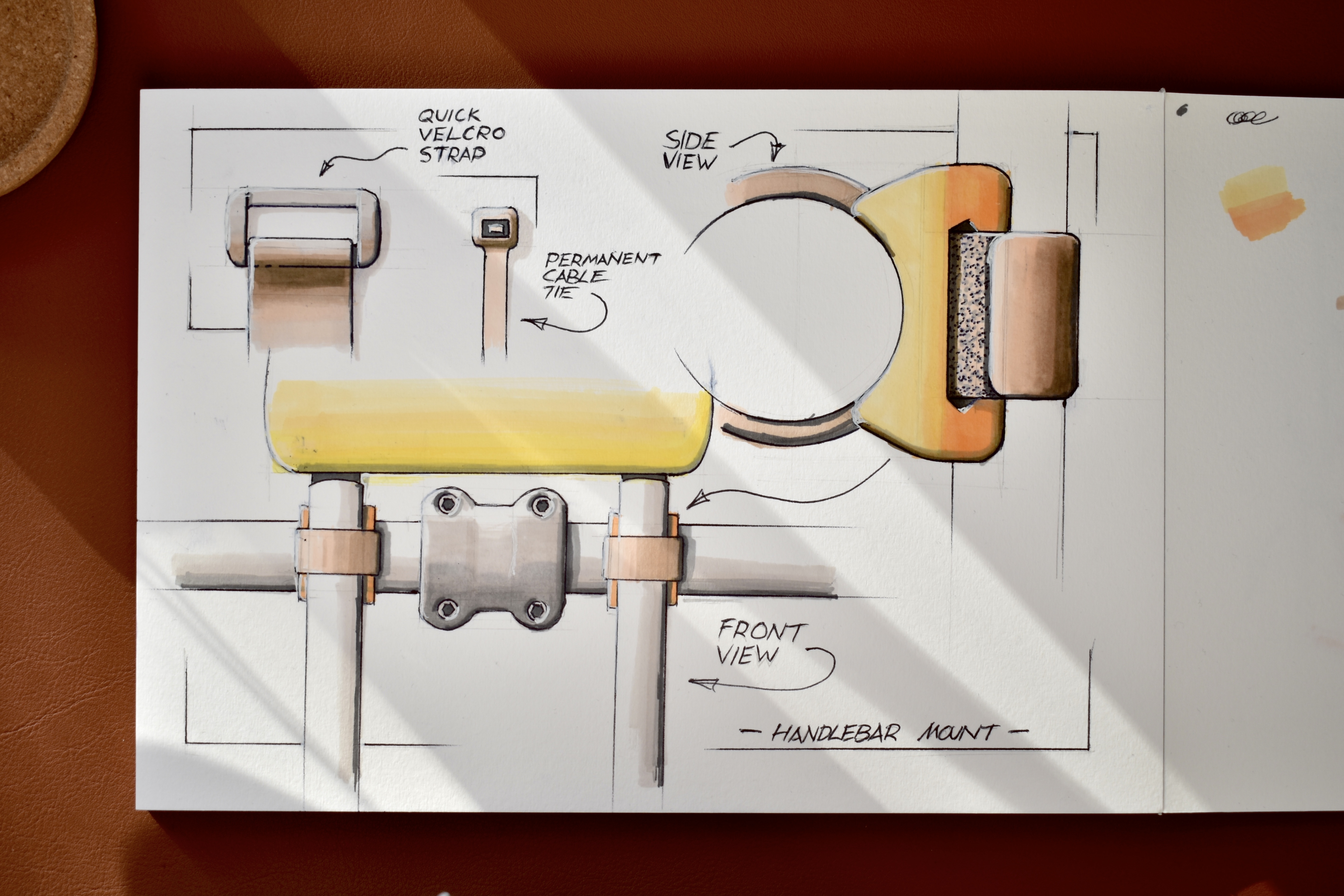

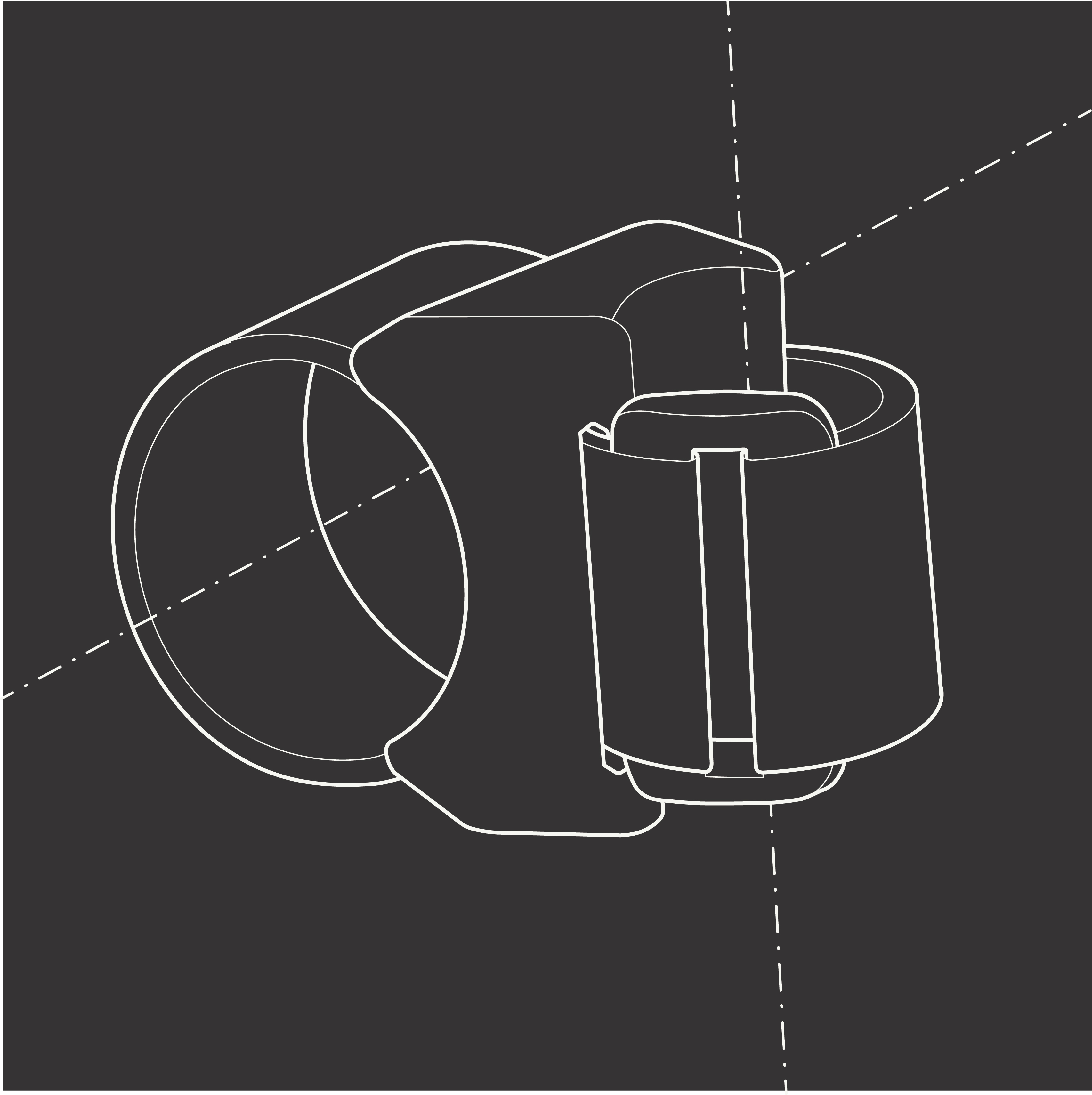

Low profile handlebar mount

A greater incentive to take an extra lock when you have no way to carry the extra one. This low-profile 3D printed handlebar mount for your D-lock, keeps it accessible and out of the way when riding. The two options: permanently fixed or removable, allows for flexibility with the use of this mount.

Also check out these!