rethinking billet gear knobs

I have never really liked many aftermarket gear knobs, and

those that I did cost an arm and a leg.

When offered a week’s free time in an engineering workshop, I couldn’t resist the urge to make my own billet gear knob, better than those I could have bought with two limbs.

When offered a week’s free time in an engineering workshop, I couldn’t resist the urge to make my own billet gear knob, better than those I could have bought with two limbs.

i couldn‘t resist the urge to make my own billet gear knob.

The design was quickly sketched out to get a feel for

proportions, then modelled in Fusion360 to not only ensure it would be as

aesthetic and ergonomic as possible, but also that manufacturing and assembly

was possible. From this, several 3D-printed prototypes were produced for

physical ergonomic checks.

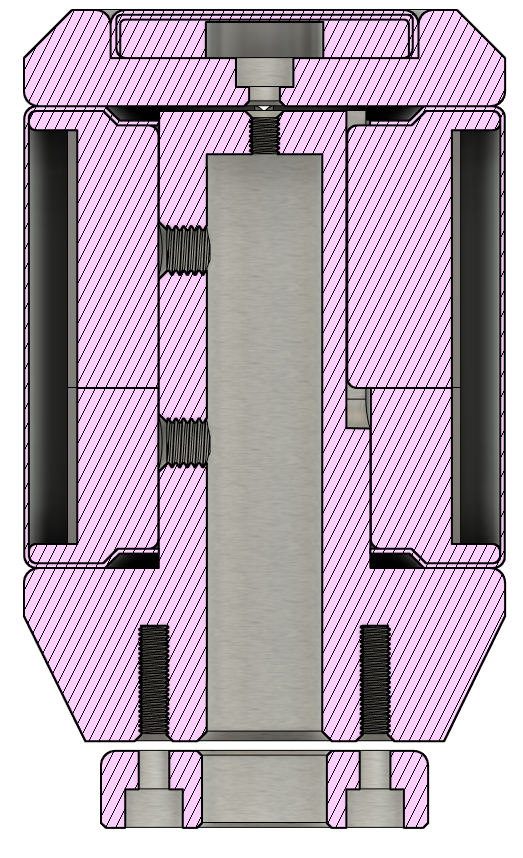

Producing the final piece consisted of an upper and lower collar manually turned from billet aluminium; a 3D-printed internal structure for crisp corners on the upholstered section, with two-layer foam (EVA and scrim) for a supportive yet supple feel.

it could be fully assembled and disassembled with one

main bolt hidden behind a magnetic cap.

It required extremely tightly tolerance to prevent any

movement inside a firm grip, yet could be fully disassembled within minutes.

also check out these!

© Jam Scones Design 2025. all rights reserved.